Product Description

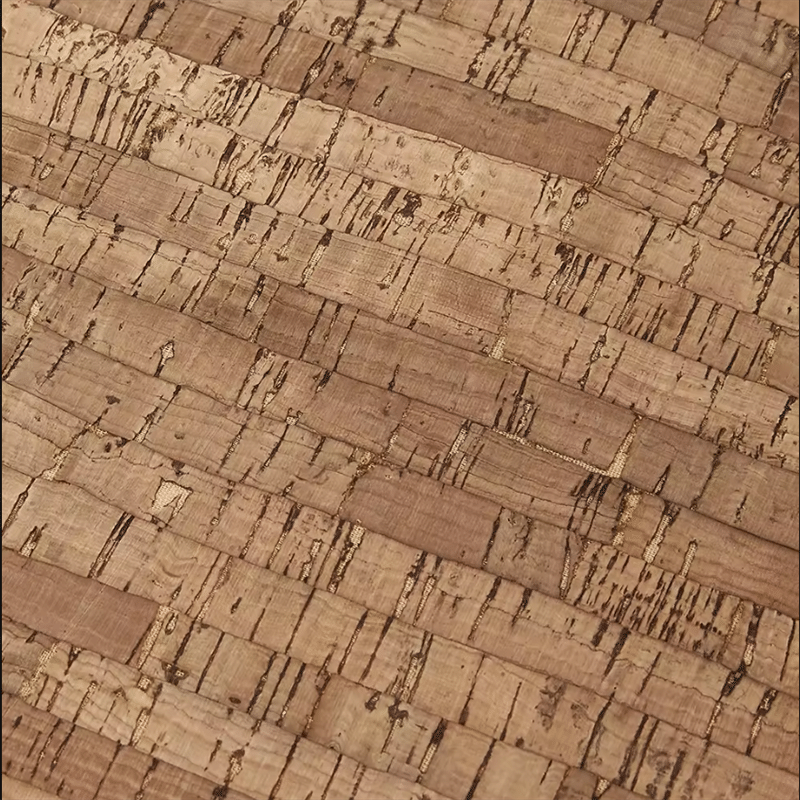

The cork fabric is taken from the bark of the Portuguese cork oak tree, a renewable resource because the trees are not cut down to collect the cork, only the bark is peeled off to obtain the cork, as well as a new layer of cork peeled off the outside bark, the cork bark will begin to regenerate. Therefore, the cork collection will not cause any harm or damage to the cork oak.

Cork is one of the most sustainable products. Cork is very durable, impervious to water, vegan, environmentally friendly, 100% natural, lightweight, recyclable, renewable water resistant, abrasion resistant, biodegradable, and does not absorb dust, thus preventing allergies. No animal products are used or tested on animals.

The raw cork material can be harvested repeatedly in cycles of 8 to 9 years, with more than a dozen bark harvests from a single mature tree. During the conversion of one kilogram of cork, 50 kg of CO2 is absorbed from the atmosphere.

Cork forests absorb 14 million tons of CO2 per year, while being one of the world’s 36 biodiversity hotspots, home to 135 species of plants and 42 species of birds.

By using products made from cork, we are contributing to the fight against climate change.

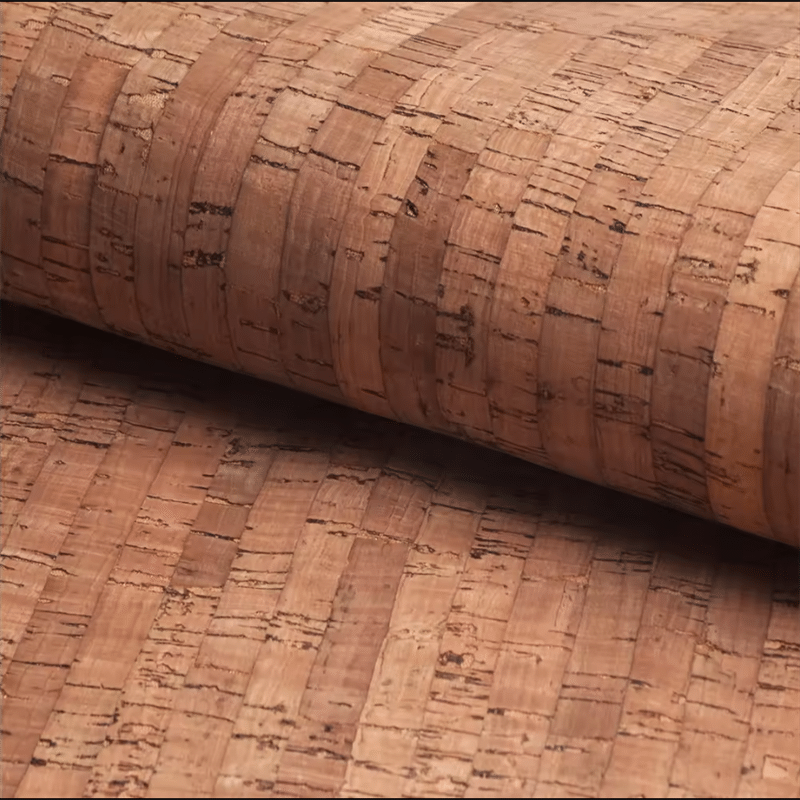

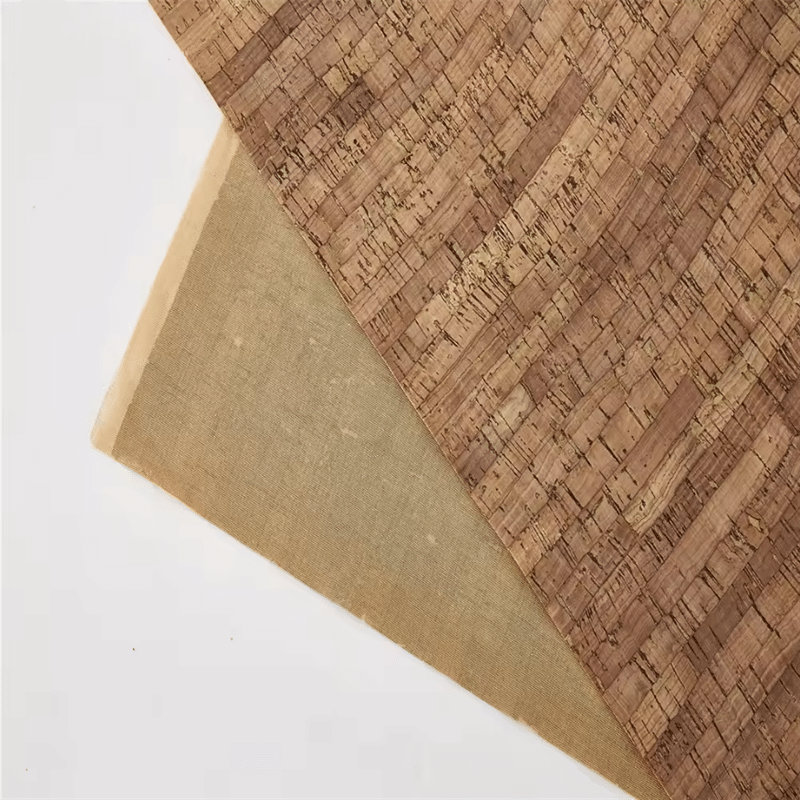

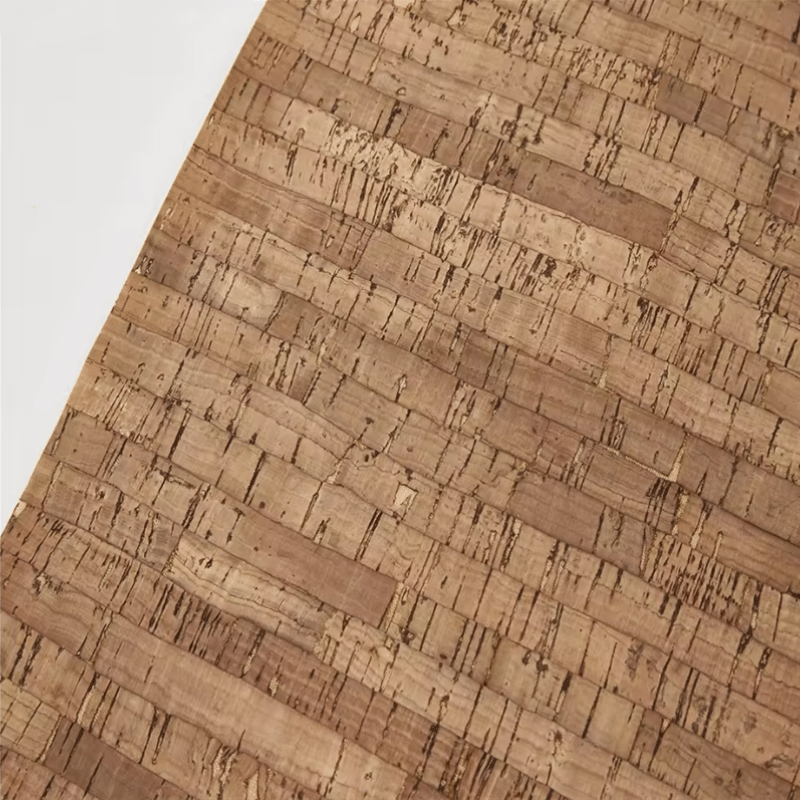

Cork fabrics are made from 100% vegan, eco-friendly and natural cork. Most products are handmade, and these thin cork sheets are laminated to the fabric support backing using a specialized proprietary technique. Cork fabrics are soft to the touch, high quality and pliable. It is the perfect alternative to animal leather.

Cork is a completely waterproof material and you can get it wet without fear.You can gently wipe the stain with water or soapy water until it disappears. Allow it to dry naturally in a horizontal position to retain its shape. Regular cleaning of the cork bag is the best way to improve its durability.

Product Overview

| Product Name | Vegan Cork PU Leather |

| Material | It is made from the bark of cork oak tree, then attached to a backing (cotton, linen, or PU backing) |

| Usage | Home Textile, Decorative, Chair, Bag, Furniture, Sofa, Notebook, Gloves, Car Seat, Car, Shoes, Bedding, Mattress, Upholstery, Luggage, Bags,Purses & Totes, Bridal/Special Occasion, Home Decor |

| Test ltem | REACH,6P,7P,EN-71,ROHS,DMF,DMFA |

| Color | Customized Color |

| Type | Vegan Leather |

| MOQ | 300 Meters |

| Feature | Elastic and has good resilience; it has strong stability and is not easy to crack and warp; it is anti-slip and has high friction; it is sound-insulating and vibration-resistant, and its material is excellent; it is mildew-proof and mildew-resistant, and has outstanding performance. |

| Place of Origin | Guangdong, China |

| Backing Technics | nonwoven |

| Pattern | Customized Patterns |

| Width | 1.35m |

| Thickness | 0.3mm-1.0mm |

| Brand Name | QS |

| Sample | Free sample |

| Payment Terms | T/T,T/C,PAYPAL,WEST UNION,MONEY GRAM |

| Backing | All kinds of backing can be customized |

| Port | Guangzhou/shenzhen Port |

| Delivery Time | 15 to 20 days after deposit |

| Advantage | High Quanlity |

Product Features

Infant and child level

waterproof

Breathable

0 formaldehyde

Easy to clean

Scratch resistant

Sustainable development

new materials

sun protection and cold resistance

flame retardant

solvent-free

mildew-proof and antibacterial

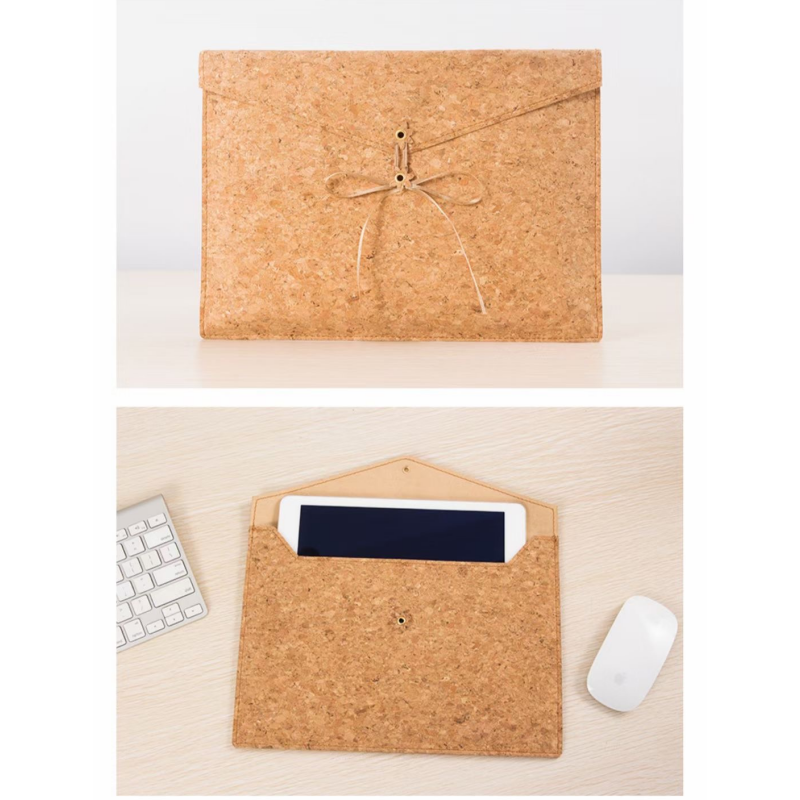

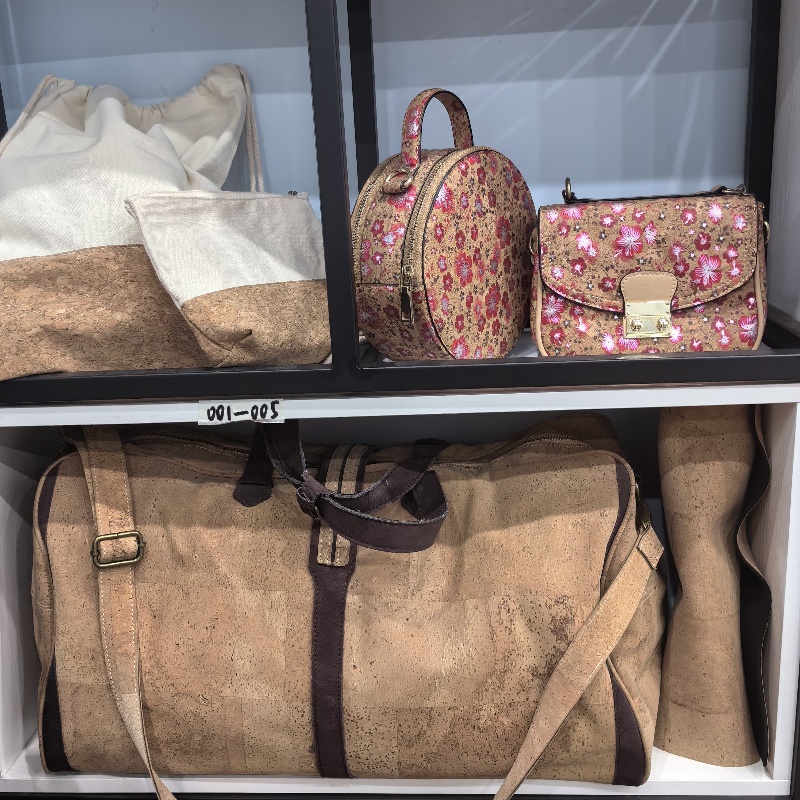

Vegan Cork PU Leather Application

Cork leather is a material made of cork and natural rubber mixture, its appearance is similar to leather, but does not contain animal skin, so it has better environmental performance. Cork is derived from the bark of the Mediterranean cork tree, which is dried for six months after harvest and then boiled and steamed to increase its elasticity. By heating and pressurizing, the cork is treated into lumps, which can be cut into thin layers to form a leather-like material, depending on the needs of different applications

the characteristics of cork leather:

1. It has very high wear resistance and waterproof performance, suitable for making high-grade leather boots, bags and so on.

2. Good softness, very similar to leather material, and easy to clean and dirt resistance, very suitable for making insoles and so on.

3. Good environmental performance, and animal skin is very different, it does not contain any harmful substances, will not cause any harm to the human body and the environment.

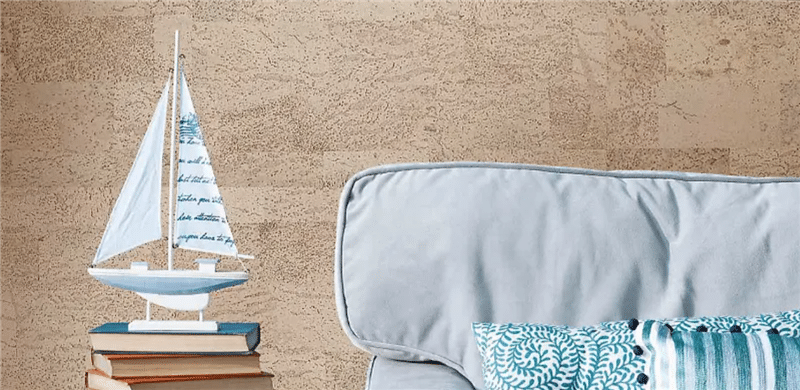

4. With better air tightness and insulation, suitable for home, furniture and other fields.

Cork leather is loved by consumers for its unique look and feel. It not only has the natural beauty of wood, but also has the durability and practicality of leather. Therefore, cork leather has a wide range of applications in furniture, car interiors, footwear, handbags and decorations.

1. Furniture

Cork leather can be used to make furniture such as sofas, chairs, beds, etc. Its natural beauty and comfort make it the first choice for many families. In addition, cork leather has the advantage of being easy to clean and maintain, making it an ideal choice for furniture manufacturers.

2. Car interior

Cork leather is also widely used in automotive interiors. It can be used to make parts such as seats, steering wheels, door panels, etc., adding natural beauty and luxury to the interior of the car. Additionally, cork leather is water-, stain- and abrasion-resistant, making it an ideal choice for car manufacturers.

3. Shoes and handbags

Cork leather can be used to make accessories such as shoes and handbags, and its unique look and feel has made it a new favorite in the fashion world. Additionally, cork leather offers durability and practicality, making it an ideal choice for consumers.

4. Decorations

Cork leather can be used to make various decorations, such as picture frames, tableware, lamps, etc. Its natural beauty and unique texture make it ideal for home decoration.

Our Certificate

Our Service

1. Payment Term:

Usually T/T in advance, Weaterm Union or Moneygram is also acceptable,It's changeable according to client's need.

2. Custom Product:

Welcome to custom Logo & design if have custom drawing document or sample.

Please kindly advice your custom needed, let us desigh high quality products for you.

3. Custom Packing:

We provide a wide range of packing options to suit your needs insert card ,PP film, OPP film, shrinking film, Poly bag with zipper,carton, pallet, etc.

4: Delivery Time:

Usually 20-30 days after order confirmed.

Urgent order can be finished 10-15 days.

5. MOQ:

Negotiable for existing design, try our best to promote good long-term cooperation.

Product Packaging

The materials are usually packed as rolls! There are 40-60 yards one roll, the quantity depends on the thickness and weights of the materials. The standard is easy to move by manpower.

We'll use clear plastic bag for the inside

packing. For the outside packing, we'll use the abrasion resistance plastic woven bag for the outside packing.

Shipping Mark will be made according to the customer request, and cemented on the two ends of the material rolls in order to see it clearly.

Contact us