Product Description

PU leather is a kind of synthetic leather, whose full name is polyurethane synthetic leather. It is an artificial leather made from polyurethane resin and other additives through a series of chemical reactions. PU leather is very close to natural leather in appearance, feel and performance, so it has been widely used in clothing, footwear, furniture, bags and other fields.

First of all, the raw material of PU leather is mainly polyurethane resin, which is a polymer compound with good elasticity and wear resistance, and can well simulate the texture of natural leather. Compared with natural leather, the production process of PU leather is more environmentally friendly, does not require a large amount of animal fur, reduces harm to animals, and is in line with the concept of sustainable development in modern society.

Secondly, PU leather has many excellent properties. The first is wear resistance. PU leather has been specially treated to make the surface smoother, less prone to wear and tear, and more durable. The second is the waterproof performance. The surface of PU leather is usually treated with waterproofing, which makes it difficult for water to penetrate and easy to clean. It is an ideal material for furniture, car seats and other materials. In addition, PU leather also has the characteristics of good softness, light texture, and easy processing, which can meet the needs of various uses.

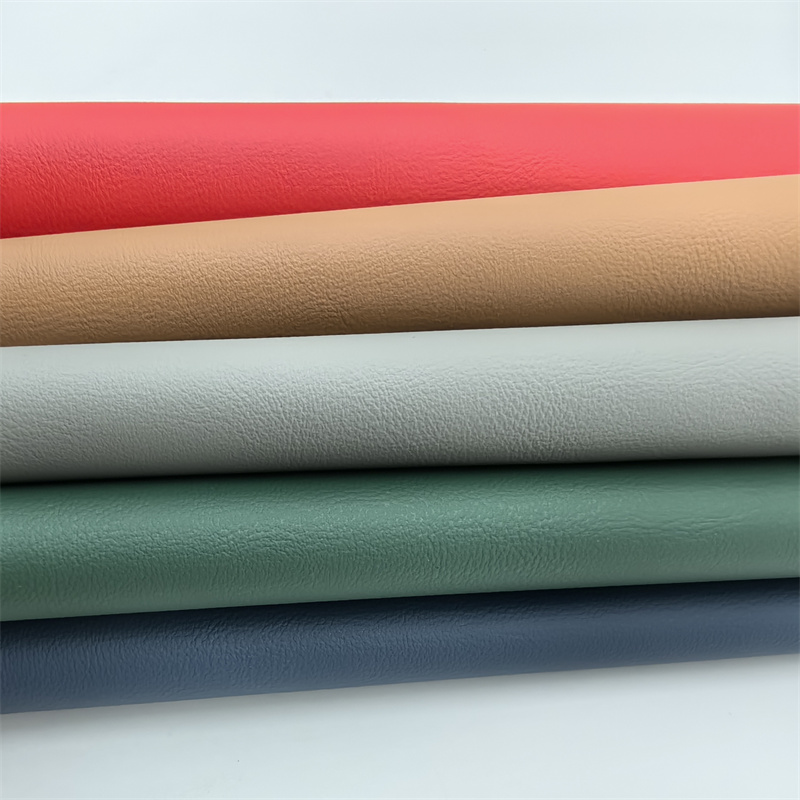

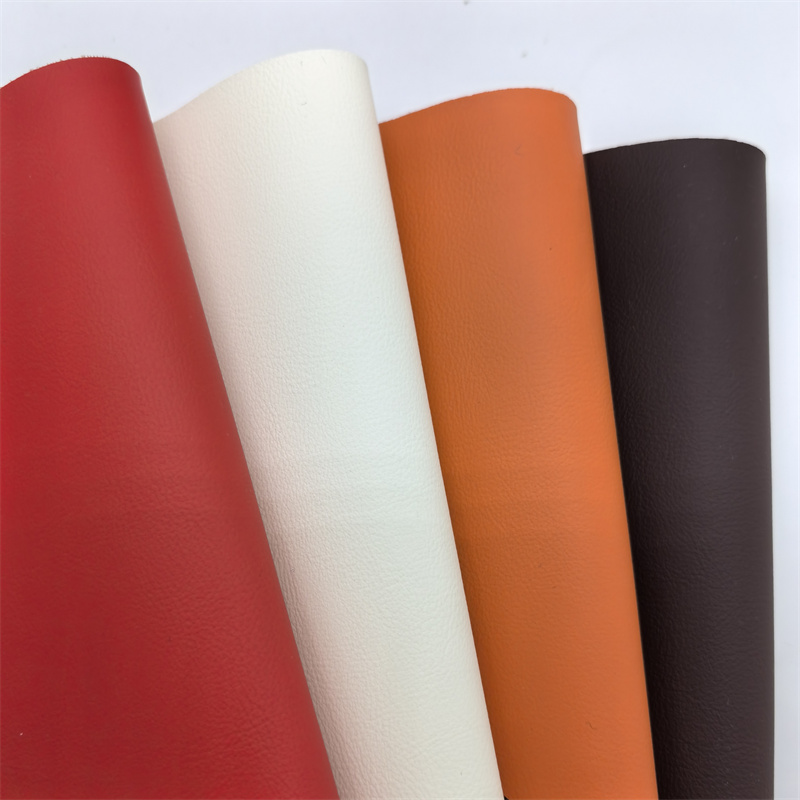

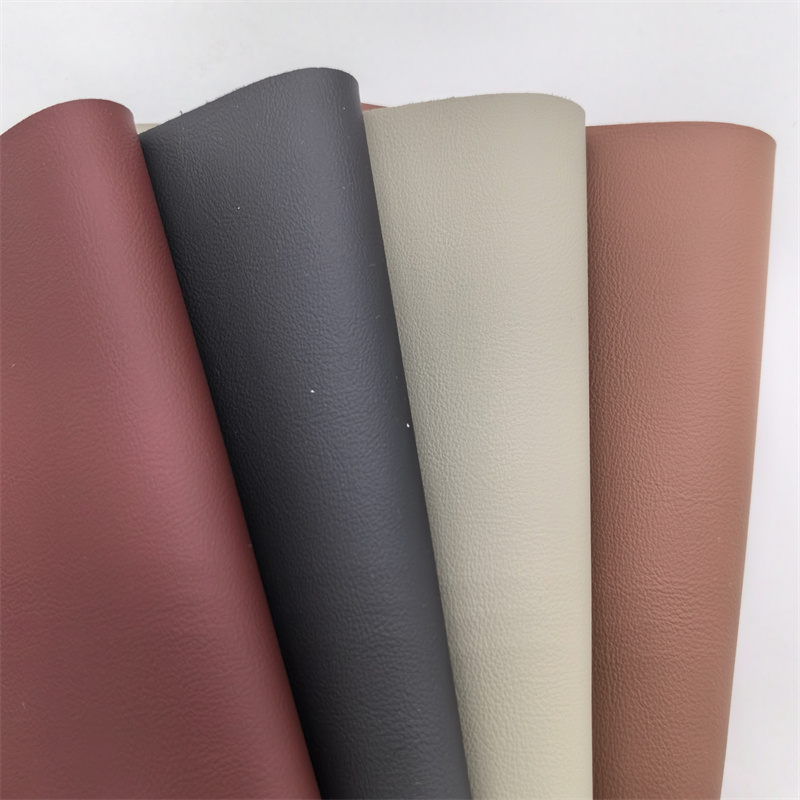

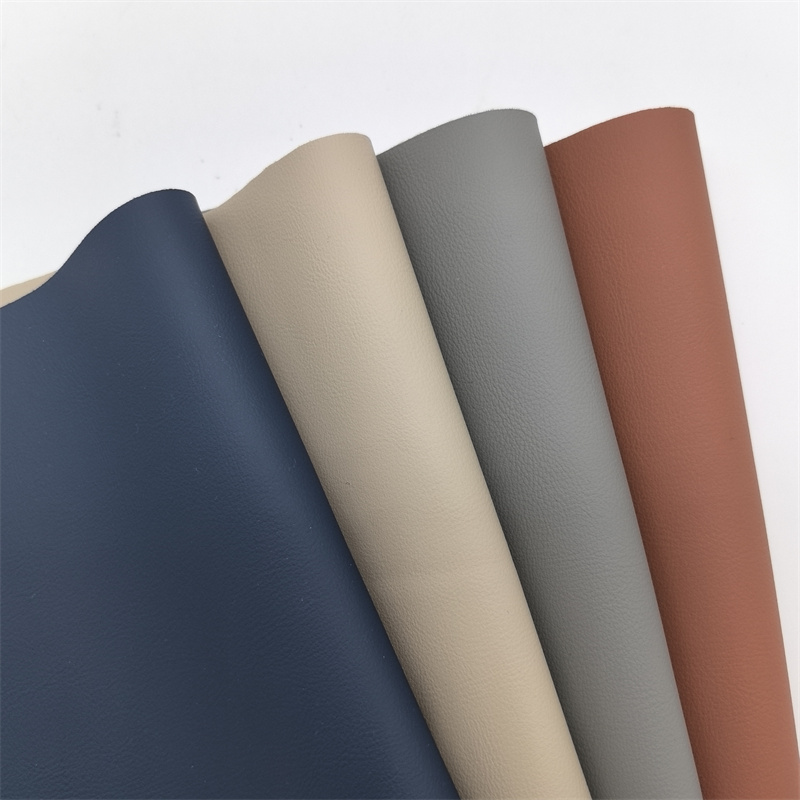

Furthermore, the appearance of PU leather is also very good. Since PU leather is a man-made material, it can be dyed, printed and other treatments according to the needs of designers. It has rich colors and diverse patterns, which can meet the aesthetic needs of different consumers. At the same time, the surface texture of PU leather can also simulate natural leather, making it more realistic and difficult to distinguish authenticity from fake.

In general, PU leather is an excellent synthetic leather material with good environmental performance, wear resistance, waterproof performance and excellent appearance.

Product Overview

| Product Name | PU synthetic leather |

| Material | PVC / 100%PU / 100%polyester / Fabric / Suede / Microfiber / Suede Leather |

| Usage | Home Textile, Decorative, Chair, Bag, Furniture, Sofa, Notebook, Gloves, Car Seat, Car, Shoes, Bedding, Mattress, Upholstery, Luggage, Bags,Purses & Totes, Bridal/Special Occasion, Home Decor |

| Test ltem | REACH,6P,7P,EN-71,ROHS,DMF,DMFA |

| Color | Customized Color |

| Type | Artifical Leather |

| MOQ | 300 Meters |

| Feature | Waterproof, Elastic, Abrasion-Resistant, Metallic, stain Resistant, Stretch, Water Resistant, QUICK-DRY, Wrinkle Resistant, wind proof |

| Place of Origin | Guangdong, China |

| Backing Technics | nonwoven |

| Pattern | Customized Patterns |

| Width | 1.35m |

| Thickness | 0.4mm-1.8mm |

| Brand Name | QS |

| Sample | Free sample |

| Payment Terms | T/T,T/C,PAYPAL,WEST UNION,MONEY GRAM |

| Backing | All kinds of backing can be customized |

| Port | Guangzhou/shenzhen Port |

| Delivery Time | 15 to 20 days after deposit |

| Advantage | High Quality |

Product Features

Infant and child level

waterproof

Breathable

0 formaldehyde

Easy to clean

Scratch resistant

Sustainable development

new materials

sun protection and cold resistance

flame retardant

solvent-free

mildew-proof and antibacterial

PU Leather Application

PU Leather is mainly used in shoe making, clothing, luggage, clothing, furniture, automobiles, aircraft, railway locomotives, shipbuilding, military industry and other industries.

● Furniture industry

● Automobile industry

● Packaging industry

● Footwear manufacturing

● Other industries

Our Certificate

Our Service

1. Payment Term:

Usually T/T in advance, Weaterm Union or Moneygram is also acceptable,It's changeable according to client's need.

2. Custom Product:

Welcome to custom Logo & design if have custom drawing document or sample.

Please kindly advice your custom needed, let us desigh high quality products for you.

3. Custom Packing:

We provide a wide range of packing options to suit your needs insert card ,PP film, OPP film, shrinking film, Poly bag with zipper,carton, pallet, etc.

4: Delivery Time:

Usually 20-30 days after order confirmed.

Urgent order can be finished 10-15 days.

5. MOQ:

Negotiable for existing design, try our best to promote good long-term cooperation.

Product Packaging

The materials are usually packed as rolls! There are 40-60 yards one roll, the quantity depends on the thickness and weights of the materials. The standard is easy to move by manpower.

We'll use clear plastic bag for the inside

packing. For the outside packing, we'll use the abrasion resistance plastic woven bag for the outside packing.

Shipping Mark will be made according to the customer request, and cemented on the two ends of the material rolls in order to see it clearly.

Contact us