Product Description

The production process of natural cork leather mainly includes the following steps:

Harvested and dried. The bark of the Mediterranean cork oak is first collected and left to dry for about six months after harvest.

Boiling and steaming. The dried bark is boiled and steamed, which increases its elasticity, and formed into lumps through heat and pressure.

cutting. Depending on the application requirements, the material can be cut into thin layers to form a leather-like material1.

Special handling. To improve durability and aesthetics, additional treatments such as staining, painting, etc. may be required.

These steps work together to transform the bark of the cork oak into a material with unique properties that can be used in a variety of products.

Product Overview

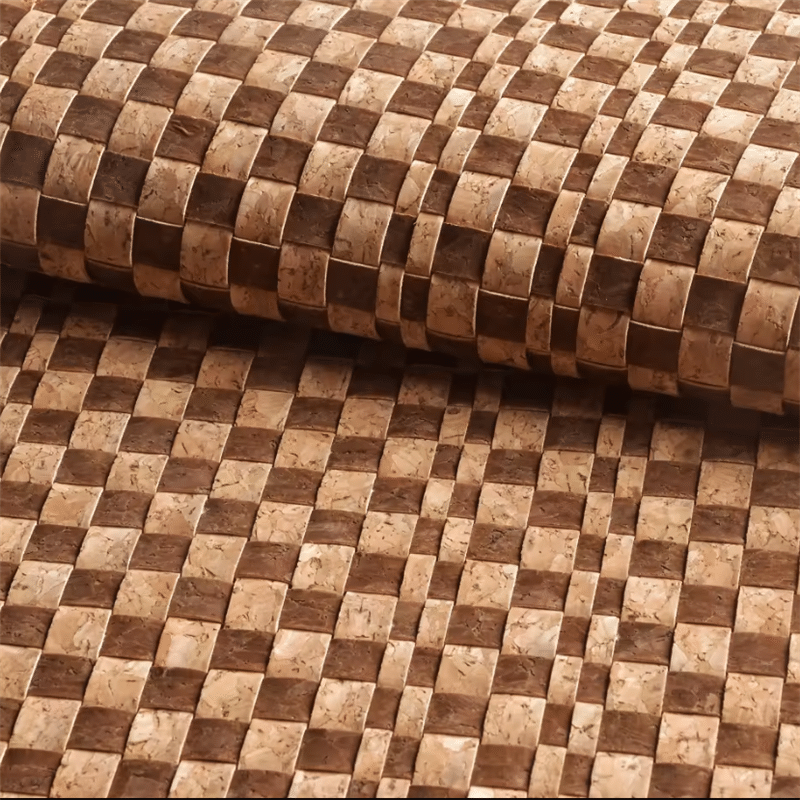

| Product Name | Vegan Cork PU Leather |

| Material | It is made from the bark of cork oak tree, then attached to a backing (cotton, linen, or PU backing) |

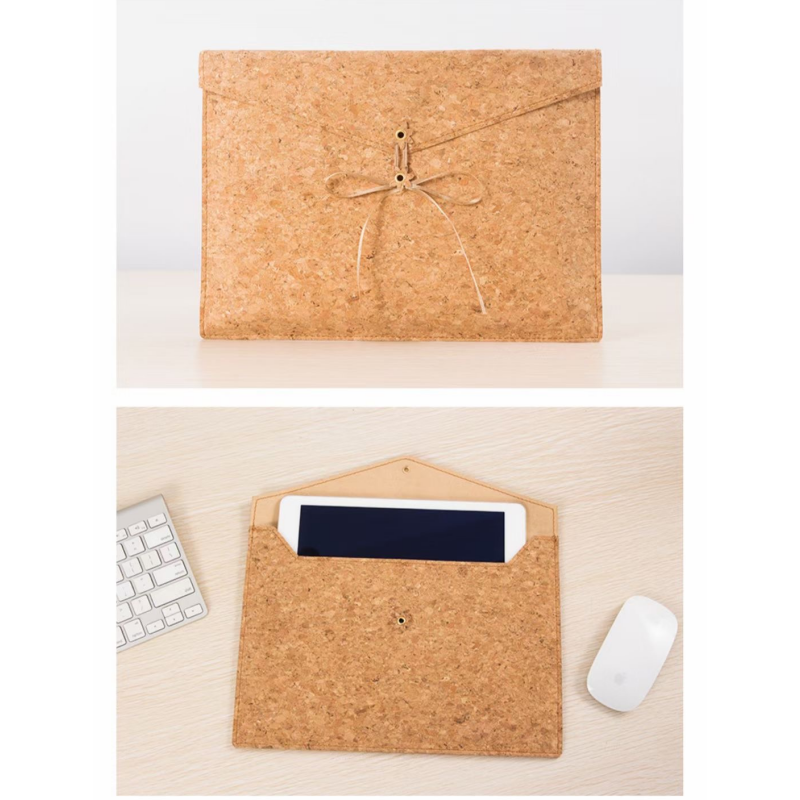

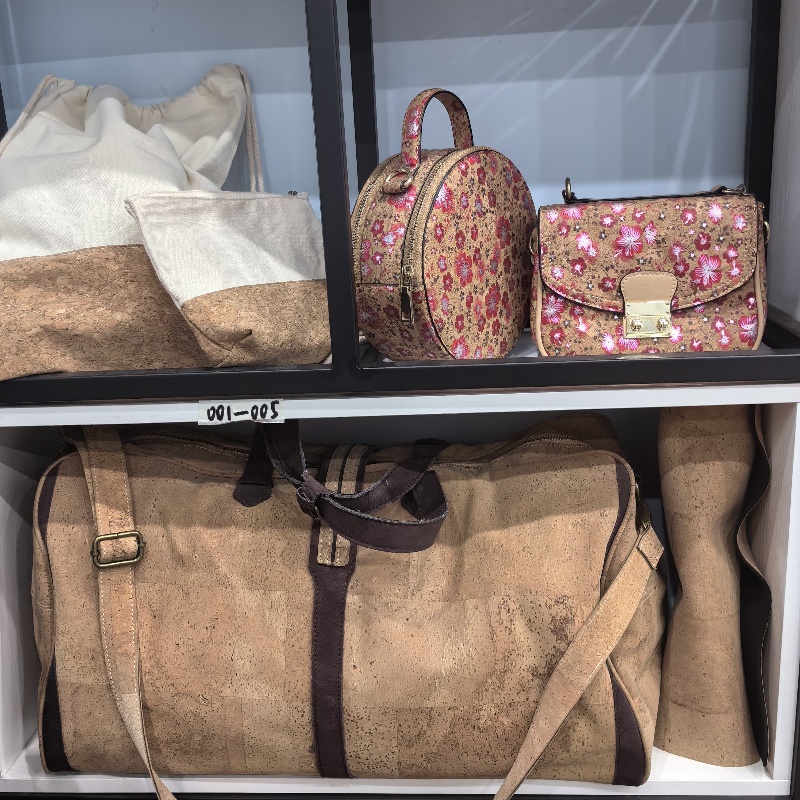

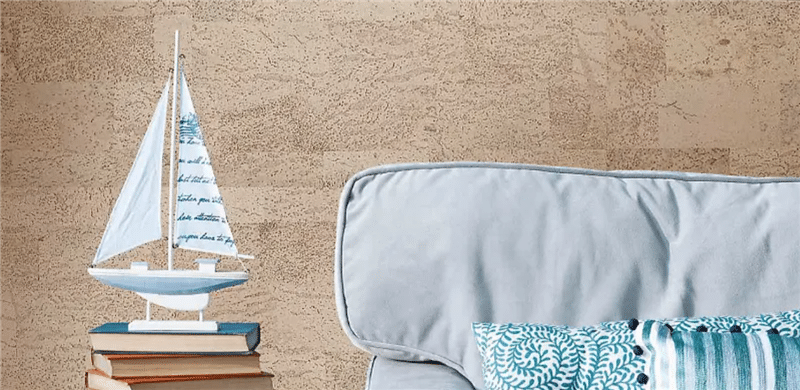

| Usage | Home Textile, Decorative, Chair, Bag, Furniture, Sofa, Notebook, Gloves, Car Seat, Car, Shoes, Bedding, Mattress, Upholstery, Luggage, Bags,Purses & Totes, Bridal/Special Occasion, Home Decor |

| Test ltem | REACH,6P,7P,EN-71,ROHS,DMF,DMFA |

| Color | Customized Color |

| Type | Vegan Leather |

| MOQ | 300 Meters |

| Feature | Elastic and has good resilience; it has strong stability and is not easy to crack and warp; it is anti-slip and has high friction; it is sound-insulating and vibration-resistant, and its material is excellent; it is mildew-proof and mildew-resistant, and has outstanding performance. |

| Place of Origin | Guangdong, China |

| Backing Technics | nonwoven |

| Pattern | Customized Patterns |

| Width | 1.35m |

| Thickness | 0.3mm-1.0mm |

| Brand Name | QS |

| Sample | Free sample |

| Payment Terms | T/T,T/C,PAYPAL,WEST UNION,MONEY GRAM |

| Backing | All kinds of backing can be customized |

| Port | Guangzhou/shenzhen Port |

| Delivery Time | 15 to 20 days after deposit |

| Advantage | High Quanlity |

Product Features

Infant and child level

waterproof

Breathable

0 formaldehyde

Easy to clean

Scratch resistant

Sustainable development

new materials

sun protection and cold resistance

flame retardant

solvent-free

mildew-proof and antibacterial

Vegan Cork PU Leather Application

Natural leather production methods

1. Soaking: Soak the leather in a drum to regain the moisture lost during the initial salinization process.

2. Liming: The first step to remove the fur and “expose” the leather.

3. Fat scraping: a mechanical step to remove residual fat under the skin to prevent chemical reactions in the leather later and the appearance of sour odor.

4. Cut the skin: Divide the epidermis into two or more layers. The upper layer can become "full grain" leather.

5. Pickling: A chemical step that removes lime and opens the "grain surface" pores.

6. Tanning: Stop the organic decomposition process of the cortex to obtain chemical and biological stability.

7. Screening: Select the best leather for Qiansin leather.

8. Shaving: Determine the thickness of the skin through steps in a roller machine equipped with spiral blades.

9. Retanning: determines the final appearance of the leather: feel, texture, density, and graininess.

10. Dyeing: Use dye to dye and apply it evenly on the entire thickness.

11. Filling: Lubricates the skin layer to bring better elasticity, softness and pull resistance.

12. Drying: Eliminate humidity: Lay the skin flat on the preheating plate.

13. Air-drying: Air-drying in a natural way creates the softness of the leather.

14. Softening and wetting: soften and moisturize the fibers, further softening the feel of the leather.

15. Fulling: softens, moisturizes and improves the "feel" of leather.

16. Hand polishing: improves the elegant and bright characteristics, which is called "thousand points" in tanning terminology.

17. Pruning: discard unusable parts.

18. Finishing: Determines the leather's ability to resist friction, fading and stains.

19. Ironing and embossing: These two procedures are to make the "grain" of the leather more uniform.

20. Measurement: The cortex is measured electronically to determine the size.

Our Certificate

Our Service

1. Payment Term:

Usually T/T in advance, Weaterm Union or Moneygram is also acceptable,It's changeable according to client's need.

2. Custom Product:

Welcome to custom Logo & design if have custom drawing document or sample.

Please kindly advice your custom needed, let us desigh high quality products for you.

3. Custom Packing:

We provide a wide range of packing options to suit your needs insert card ,PP film, OPP film, shrinking film, Poly bag with zipper,carton, pallet, etc.

4: Delivery Time:

Usually 20-30 days after order confirmed.

Urgent order can be finished 10-15 days.

5. MOQ:

Negotiable for existing design, try our best to promote good long-term cooperation.

Product Packaging

The materials are usually packed as rolls! There are 40-60 yards one roll, the quantity depends on the thickness and weights of the materials. The standard is easy to move by manpower.

We'll use clear plastic bag for the inside

packing. For the outside packing, we'll use the abrasion resistance plastic woven bag for the outside packing.

Shipping Mark will be made according to the customer request, and cemented on the two ends of the material rolls in order to see it clearly.

Contact us